ECO-Aire® Dryers

Clean, dry compressed air is essential when performing any kind of cleaning or blasting operation. We build these systems ourselves using high quality, industrial grade components. We offer two different sizes to choose from so there is an ECO-Aire® Dryer for everyone.

Available in two models, with either a 12V or pneumatic fan motor:

- MAXX: for use with compressors up to 250 cfm

- SUPER: for use with compressors up to 600 cfm

STAGE 1:

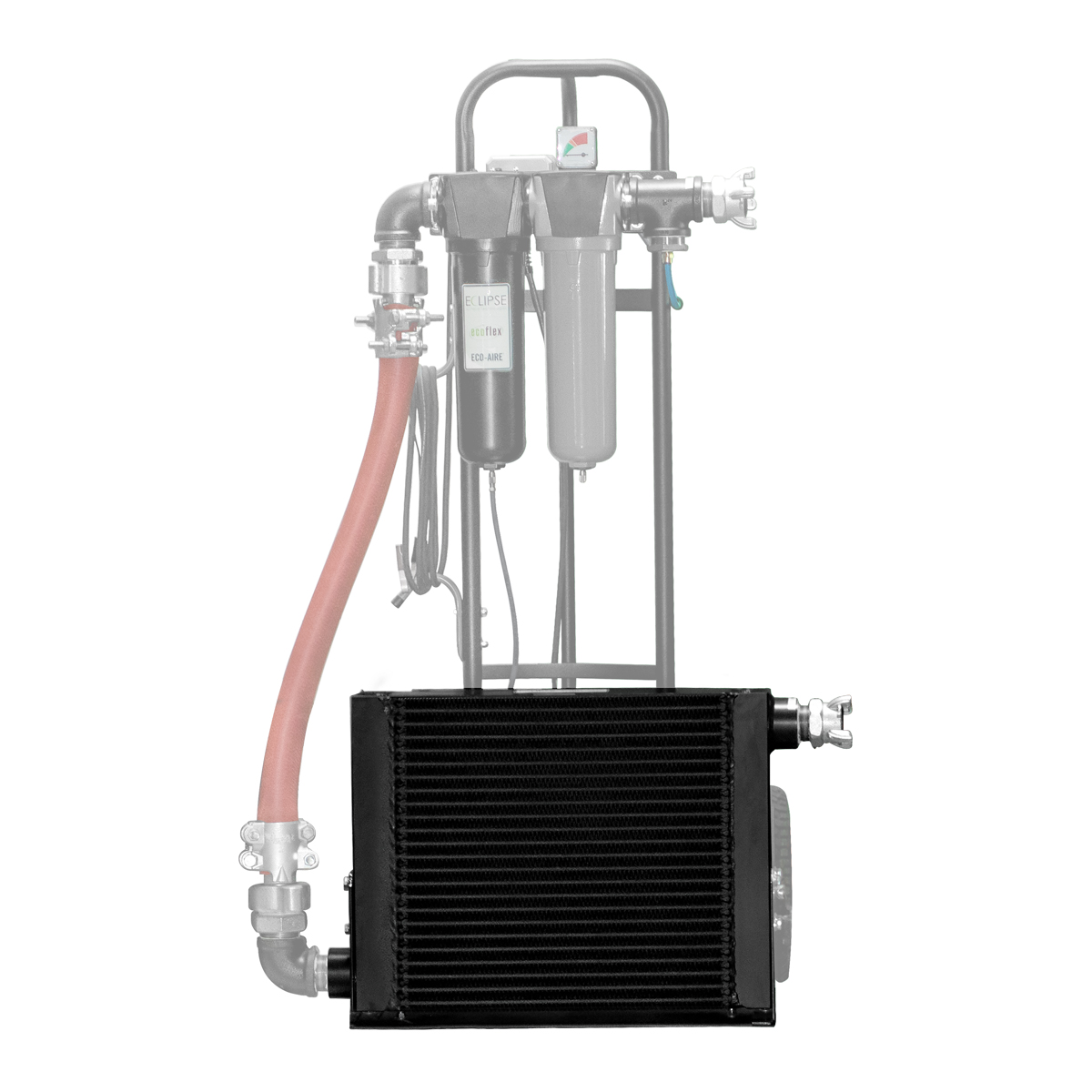

AFTERCOOLER

As the air travels through the Aftercooler,

it cools and forms condensate. We also provide a special built-in sensor so if you shut down your compressor, our Aftercooler will also shut off, preventing your battery from going dead.

STAGE 2:

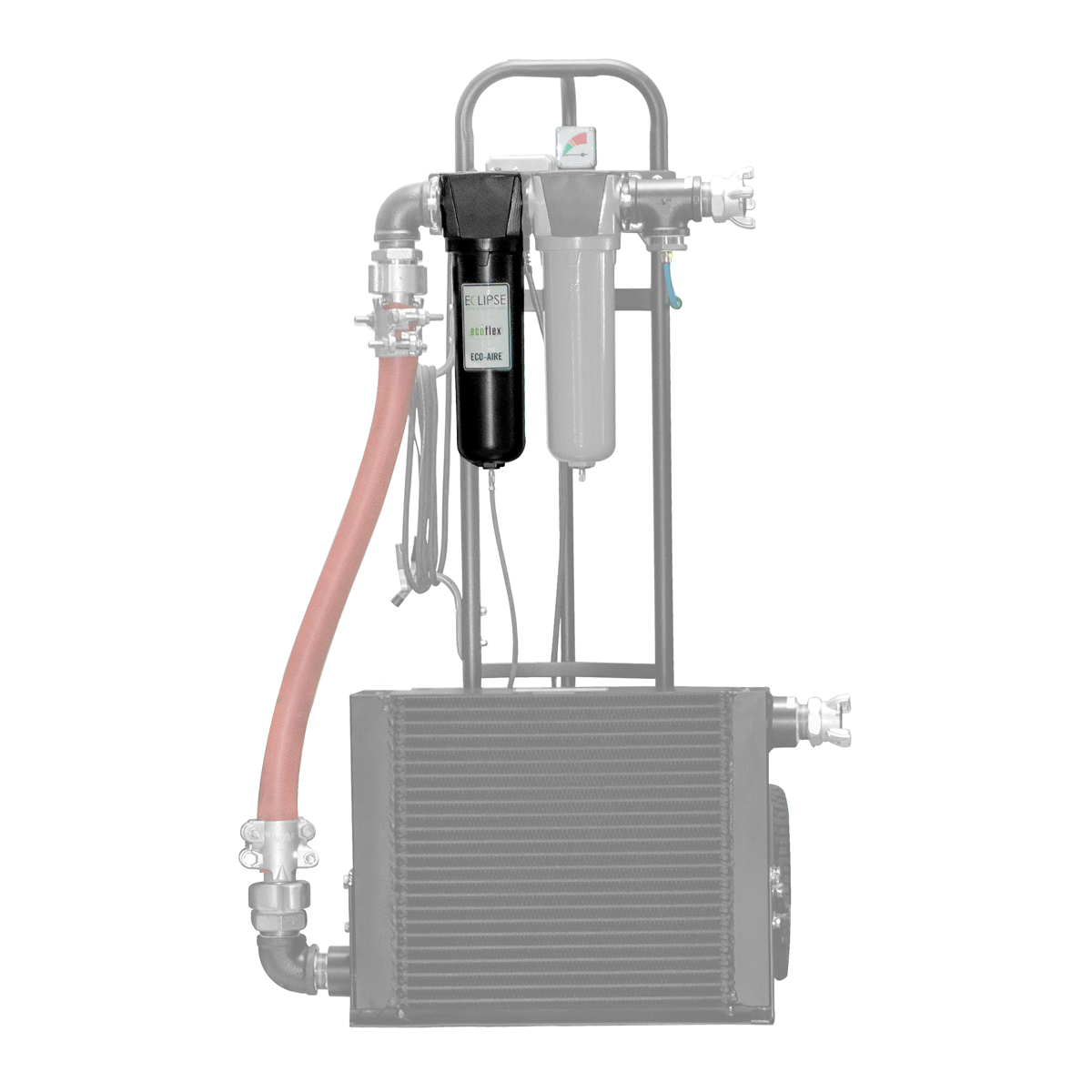

WATER SEPARATOR

This stage will extract any moisture or humidity in your compressed air, meaning the air is now cool & dry. This component traps the condensate produced by the Aftercooler then utilizes an automatic float drain.

STAGE 3:

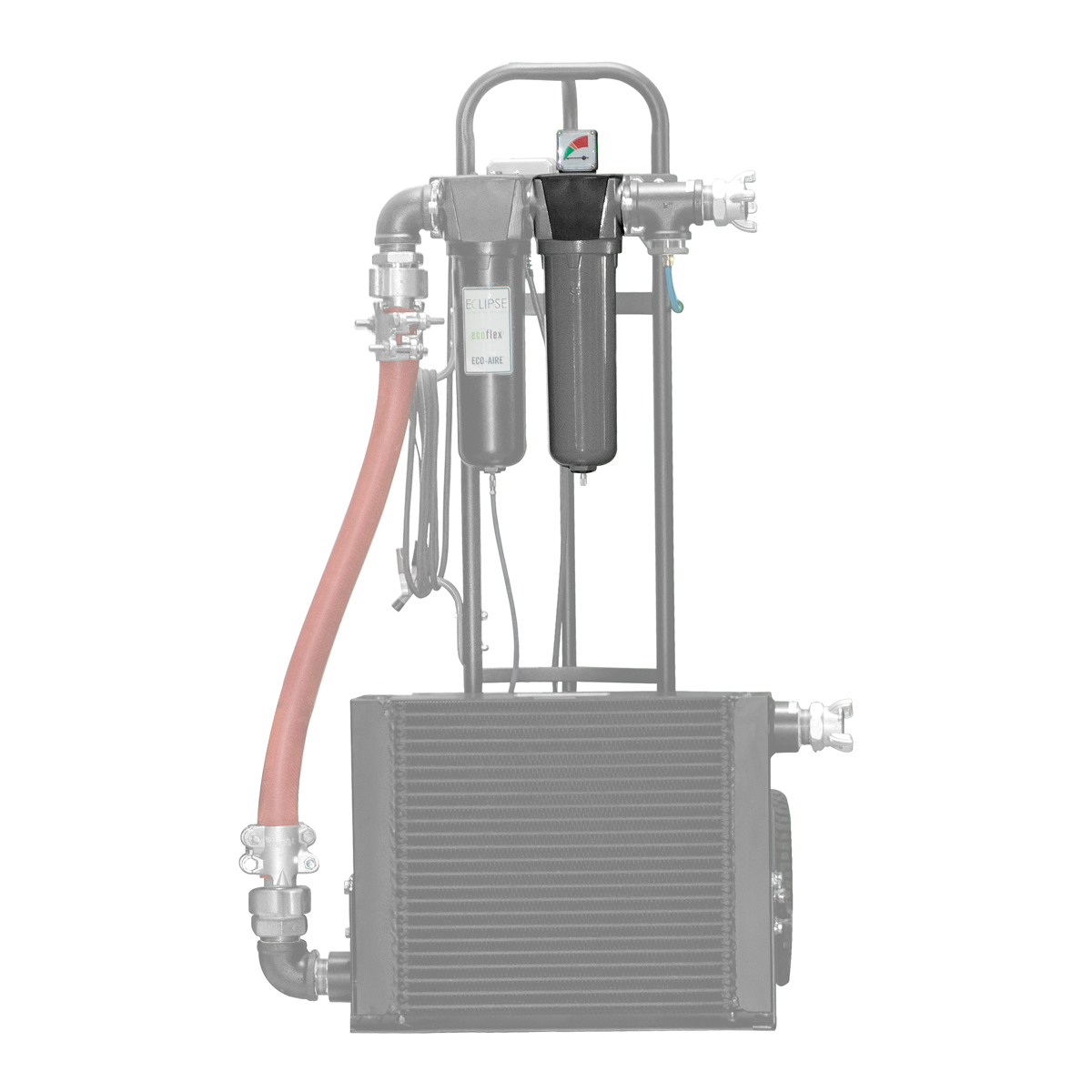

HIGH EFFICIENCY FILTER

The coalescent air filter traps any remaining contaminants including any residual lubricants, down to 1 micron. This ensures your vessel always stays clean & dry while preventing contaminants on the surface, critical for Military or SSPC compliance.

We take great pride in crafting the very best in abrasive blasting equipment and accessories for our clients. We manufacture, sell and service all of our equipment under the ClearBlast and ECO-Flex brands in Pennsylvania. That means all Eclipse Surface Technologies’ equipment is made in the USA!

The majority of ECO-AIRE® Dryers we sell are 12V systems which easily clip onto your air compressor battery to operate. With other systems on the market, if you forget to disconnect the clips when the compressor is not running, it will completely drain the battery.

Every ECO-AIRE® Dryer includes a sensor that will shut down the aftercooler once it doesn’t detect air flow, ensuring your battery remains charged and ready to go.

We professionally mount & connect all of these components onto a heavy duty hand truck in our facility. ECO-AIRE® Dryers travels well in a pick-up truck or can even fit into an SUV if need be.

| Model: | MAXX (12V) |

MAXX (pneumatic) |

SUPER (12V) |

SUPER (pneumatic) |

| Flow Rate: | up to 250 cfm | up to 250 cfm | up to 600 cfm | up to 600 cfm |

| Piping Diameter: | 1.25 in. | 1.25 in. | 3 in. | 3 in. |

| Air Connection: | 2 lug ‘Chicago’ style OR 4 lug |

2 lug ‘Chicago’ style OR 4 lug |

4 lug | 4 lug |

| Fan Motor: | 12V DC | Pneumatic | 12V DC | Pneumatic |

| Weight: | 90 lbs. | 100 lbs. | 215 lbs. | 235 lbs. |

| Dimensions: | 18.5″L x 30″ W x 48″ H |

18.5″ L x 30″ W x 48″ H |

26.5″ L x 39″ W x 61.5″ H |

26.5″ L x 39″ W x 61.5″ H |